Research

We spend a lot of time carefully selecting the best cacao beans. We sample and test many varieties and variations of beans, sugars, and experiment with combinations of mixes and roasting profiles. Only after we are totally satisfied do we move the recipe concept from our testing lab to our production kitchen.

Sort and Classify

We carefully sort through each sack of beans by hand to ensure only the finest quality beans make it into our chocolate. After the sorting, our beans go through an initial classifying process which carefully removes any damaged beans or foreign material such as stones, sticks or any other objects that were included during the fermentation or bean drying process at the point of origin.

Roast

We roast small micro batches of <10lbs beans at a time in our custom designed cocoa roaster. We found that roasting smaller batches provides us the level of control we need to meet the precise temperature profile required of the various bean types we roast. Roasting procedures for each bean type vary quite a lot, as beans from different parts of the world require very different roasting times and temperatures to bring out the best flavor of the chocolate. The roasting is a science in of itself and that’s why we opted to design and build a perfect roaster specifically for cacao as opposed to refurbishing or trying to modify a coffee a roaster machine as most bean-to-bar chocolate makers do. Our gas fired roaster constantly moves waves of heat in and around the rotating bean drum, but the flame never actually comes in direct contact with the beans. This unique process allows us to bring out the best flavor of the beans.

Winnow

Removing the husk from the nib. Our custom built winnowing machine is a machine with a series of vibrating sieves positioned under a series of vacuum units. The crushed beans fall onto the mechanical vibrating sieves from the bean breaker, and because the husk is lighter than the actual cacao nib, the lighter husk pieces are vacuumed off leaving only the cacao nib to be further processed. This aspect of the process is also extremely important, as you do want any husk or bean shell left behind.

We Grind and Conch

Our grinding process is different to other chocolate makers in that we introduced more refining steps to prevent over heating or burning of the chocolate liqueur that can happen over prolonged single grinding processes. The art of making perfect chocolate is all about temperature controlled efficient particle reduction. Our cacao nib is mixed with pure cane sugar over a two day time period and ground using a variety of refining machines to bring the finish particle size of less than 20 micron. The reason for this level of fine grinding is to give a perfectly smooth silk taste. We grind our nibs and sugar until we reach the desired texture and until the cacao’s natural acids left over from the fermentation have been released (conched). We are meticulous in this process, being careful not to over grind or over conch. Our grinding process include a variety of different particle reduction methods which entail moving the cacao through a colloid mill, removing the grit by counching in large granite stone mélange mills, and finally through a ball mill and roll refiner. The extra refining steps we take are so evident in our final product.

Age

We pour the finished chocolate into 5lb blocks, and wrap and stored it for a minimum of 1 month. This ageing process allows the remaining acidity in the chocolate to mellow.

Melt, Temer and Mold Our Chocolate

Once the chocolate has aged, it is then re-melted and tempered. Tempering is a delicate process of heating and cooling from 46c to 26c and then back to 32c where the chocolate is set in the correct crystal structure that will give the best shine, the loudest break snap and more importantly the longest shelf life.

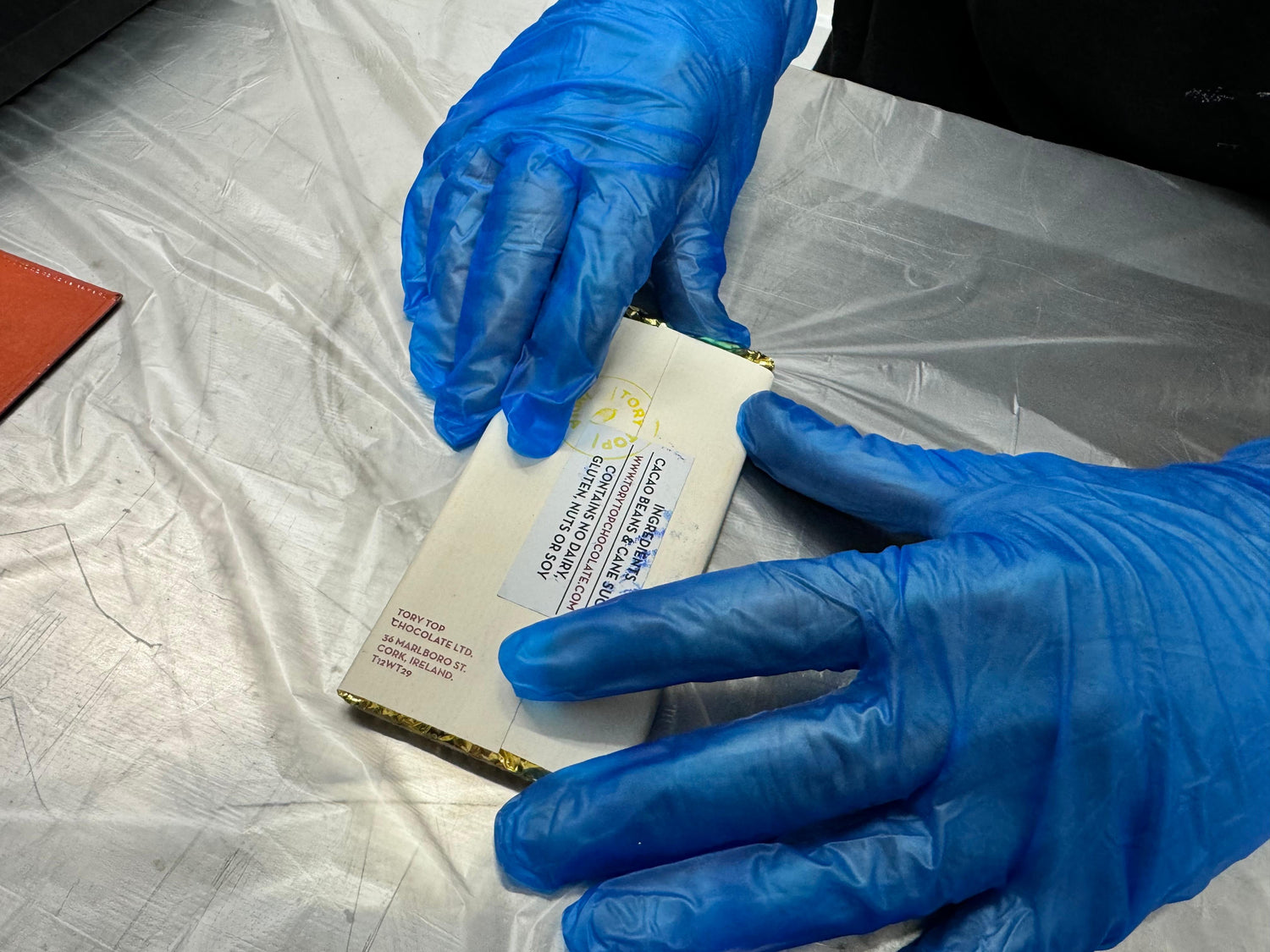

Hand Wrapping and Quality Control

It’s a personal thing for me as president of Tory Top Chocolate – I opted to hand wrap our products from the very beginning. I love the “out of package” chocolate experience and I wanted for you to experience the true aroma of our products as you slowly unfold our award-winning art wrapping and peel back the foil of our hand wrapped chocolate bars. The personalized experience really makes all the difference.

Once removed from our chocolate bar molds, we individually and carefully hand wrap each and every bar to ensure our chocolate is inspected one last time. Our chocolate is dated and packaged to meet our stringent Quality Assurance standards. As president of all things chocolate at Tory Top, it’s my way of a warm hand off of our chocolate delight to you.